Dalian pneumatic pump manufacturer is recommended as a sludge treatment method to remove water from flowing primary, concentrated or digested sludge and turn it into semi-solid or solid sludge. After dewatering, the moisture content of sludge can be reduced to 5% to 80% according to the properties of sludge and sediment and the use effect of dewatering equipment. And then dewatering the sludge is called sludge drying.

Dalian professional pneumatic pump manufacturers, mainly using natural drying method, mechanical dehydration method and granulation dehydration method. Natural drying and mechanical dewatering are ideal methods for sludge treatment. Granulation process is suitable for coagulation and sedimentation of sludge. In order to improve the dewatering performance, sludge pretreatment is usually needed before dewatering. The common pretreatment method is adding inorganic salt or polymer coagulant. In addition, there are washing and heat treatment methods.

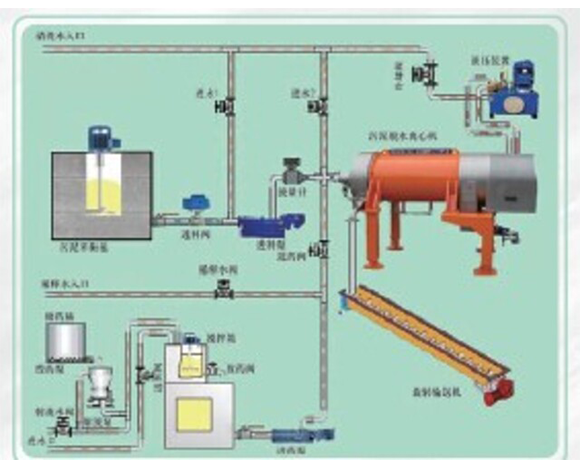

There are two methods of mechanical dehydration: filtration and centrifugation. The filter uses a filter layer to filter wet sludge (porous materials such as filter cloth and wire mesh), so that water (filtrate) can penetrate into the filter layer, while dewatered sludge (filter cake) can be filtered out. Centrifugation is the separation of sludge and water with the help of different centrifugation tendency caused by the specific gravity difference between solid and liquid in sludge. The equipment used for filtration includes vacuum filter, plate and frame filter press and belt filter.

The vacuum filter can continuously feed and discharge sludge, and runs smoothly, but there are many auxiliary equipment. The plate and frame filter press is a common equipment in chemical industry. It has high filtering thrust, low moisture content of mud cake, intermittence in and out of mud, and low production efficiency. Manual operation of the plate and frame filter press, labor intensity, most of the use of automatic mechanical operation.

Belt filter is a new type of filter, its design scheme is various, according to the dehydration principle is also different (gravity filtration, pressure filtration, capillary water absorption, granulation), but they all have a rotating belt, while carrying mud, while dewatering, or only carrying mud. Its complexity and energy consumption are similar.