Stryn liquid ring vacuum pump, liquid ring compressor and system brief description:

Systems engineering is a German based multinational group specializing in fluid products and systems with annual sales of 500 million euros. Šich is one of the world's successful fluid technology companies, the company focus on vacuum pumps and vacuum solutions, is a global manufacturer of high quality vacuum pumps. The product market covers basic chemical industry, fine chemical industry, energy, steel, medicine, electronics, photovoltaic, food and general industry. Šich pump (Shanghai) Co. , Ltd. is a wholly-owned subsidiary of stringhill. We have a complete team of production, assembly, testing, sales and maintenance service in China.

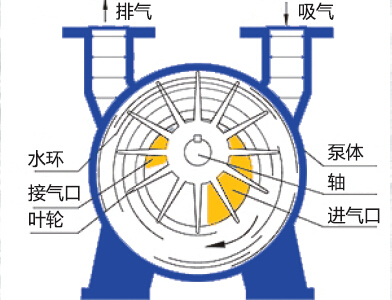

Working principle of liquid ring vacuum pump and liquid ring compressor:

The impeller of the liquid ring vacuum pump (liquid ring compressor) is installed in the cylindrical intermediate body eccentrically. When the pump is running, due to the effect of Centrifugal Force, the kinetic energy of the liquid in the pump is formed in a concentric ring next to the intermediate. The liquid ring and the blades of the rotor form a number of working chambers whose volume varies periodically. This structure enables the fluid to act as a piston in entering and exiting each working chamber. When the liquid flows out of the chamber, the gas is drawn in through the inlet through the guide plate. Conversely, when the liquid circulates into the chamber, the gas is compressed and discharged through the outlet. During the operation of the pump, it is necessary to continuously replenish the working fluid, usually water, in order to take away the heat generated in the process of gas compression and the working fluid which is discharged with the gas together. The working fluid can be recycled.

Features of liquid ring vacuum pump and liquid ring compressor:

Able to handle almost all gases and vapors, and can carry a small amount of liquid;

2. Impeller is rotating parts, no friction between metal parts, longer service life;

3. There is no lubrication in the working chamber, so there is no oil and no pollution.

4. Almost isothermal compression, the liquid ring is not easy to vaporize, high security;

5. With a wide range of material selection (such as cast iron, stainless steel, hastelloy, titanium, etc.) ,

and to adapt to a variety of operating conditions;

6. Simple installation, easy maintenance, high reliability and safety in structure and operation.

7. Safe handling of flammable, explosive and toxic gases (ATEX certified) ;

8. For highly toxic media and leak-free occasions, Sihi magnetic drive liquid ring vacuum pump provides a good solution;

9. Low running noise, small vibration; 10. Integrated sewage discharge, more convenient maintenance;

Performance parameters:

VACUUM PUMP:

COMPRESSOR:COMPRESSOR:

Features of double-stage vacuum pump and compressor:

1. Two-stage compression, each stage impeller compression ratio is small (each stage impeller compression ratio is only between 5-6) in the working process has higher reliability;

2. Each stage impeller compression ratio is small, can better prevent cavitation, while can achieve greater pressure difference, Higher Exhaust Back Pressure;

3. The working liquid temperature rise is small, the water temperature to the entrance pressure and the inspiration quantity influence is smaller, may better guarantee the entrance pressure request;

4. More effective cavitation avoidance, higher service life, and lower vibration and noise.

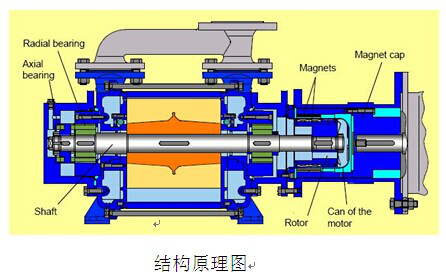

Magnetic drive vacuum pump (LEM/LEH/LPH) features:

The Stryn liquid ring vacuum pump is designed with an advanced concept of magnetic drive coupling. The unique stirling Sihi leak-free vacuum pump not only makes liquid handling more economical, but also causes less pollution to the environment because Sihi is a leak-free magnetic vacuum pump. Stryn continues to strive, and will continue to strive, to be a leader in all fields of vacuum magnetic pumps. Sihi magnetic drive liquid ring vacuum pump is a high demand, high tightness, simple, high efficiency vacuum pump. Liquid lubricated and cooled tungsten and silicon dioxide bushings provide axial and radial support to the shaft. The use of high energy density, high grade magnetic drive materials ensures safe transport during startup and overload. Modular magnetic drive systems offer a variety of options for different operating environments. The main parts of the pump are the same as those of standard pumps, and the connecting dimensions are uniform. Materials can be designed to adapt to different environments.

Liquid ring vacuum pump grade compressor, Dalian metering pump manufacturer consultation