Decanter-type Centrifugal separator

The principle of the centrifuge, Beares is the use of different specific gravity of the mixture of materials in the centrifugal force under the effect of layered settlement, to separate two-phase or multi-phase material with different specific gravity of the device. The separation process is carried out inside a rotating cylinder/truncated cone drum. The material with larger specific gravity is deposited on the inner wall of the drum and is continuously conveyed to the discharge port of the drum by the spiral inside the drum.

Beares was founded in 1886 and has been producing centrifuges for sludge dewatering for more than 130 years, the company said. As one of the oldest professional centrifuge manufacturers in the world, Beares is also one of the largest horizontal screw centrifuge manufacturers in the world. In recent years, the annual production and sales volume has been stable at around 1,000 units, in the horizontal screw centrifuge manufacturers in a leading position. At present, there are thirty-eight thousand or so beiares group centrifuges operating stably and efficiently in various industries all over the world. In addition to producing conventional decanter centrifuges, Beares also develops, develops, and manufactures decanter centrifuges with special configurations. Beares's innovative and unique structural design has many advantages over conventional decanters, which can be used for industrial and municipal sludge thickening and dewatering. Practical application shows that Beares's special designed horizontal screw centrifuges have low energy consumption, low drug consumption, high solid content in mud, stable operation, low noise, easy operation and management, and simple maintenance.

Features of Beares's centrifuge: movable drop point.

2. Open Spiral

3. The mud scraping device at the mud outlet of the centrifuge.

4. DRUM TUNNEL STRUCTURE

5 differential automatic adjustment system

6 complete fuselage support

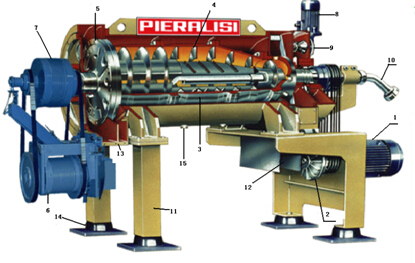

Centrifuge profile

Which metering pump manufacturer is good

DESCRIPTION OF CENTRIFUGE CONSTRUCTION:

1. Main Motor

2. Hydraulic couplings (or other driving modes)

3. Drum roll

4. Open spiral

5. Adjustable overflow Weir Plate

6. Automatic adjustment device of ROTOVARIATOR differential speed

7. Planetary gear reducer

8.Scraper Motor (patent system)

9. Sediment scraper room

10. Reciprocating adjustable feed tube

11. Brace

12. Solid phase exit

13. Overflow phase exit

14. Shock Absorption System

15. Cleaning Hole