The metering pump produced by the metering pump manufacturer is a type of equipment used for conveying liquids, which has the characteristics of accurate flow control and suitability for various liquids. It is an indispensable and important equipment in industrial production. With the continuous progress of industrial technology, the application range and performance of metering pumps will continue to improve, providing more convenient and efficient liquid transportation solutions for production in various industries.

The metering pump has the advantages of high precision, good stability, and high reliability, which can meet the demand for accurate control of fluid transportation in industrial production. It is widely used in various chemical production processes, such as the transportation of additives, mixing and transportation of solvents, wastewater treatment systems, etc. In the petroleum industry, metering pumps are often used for the measurement and transportation of crude oil, lubricating oil, and chemical products, ensuring accurate measurement and transportation of liquids in the production process. In the food industry, metering pumps can be used for conveying liquids such as sauces, fruit puree, and alcohol, ensuring product quality and production efficiency.

How to adjust the position and function of metering pumps in chemical process flow introduced by metering pump manufacturers?

The position adjustment of the metering pump is very important. In chemical process flow, metering pumps are usually installed in pipeline systems to ensure that materials can be accurately transported to designated locations. The position of the metering pump should be as close as possible to the equipment or container that needs to input materials, in order to reduce pressure loss and leakage risk during the conveying process. In addition, the location of the metering pump should also consider the convenience of maintenance and cleaning to ensure that the metering pump can operate stably for a long time.

Secondly, adjusting the function of the metering pump is also crucial. In the chemical process flow, the main function of the metering pump is to transfer an accurate amount of material to a designated location to ensure the accuracy and stability of the process. The adjustment of the function of the metering pump includes the following aspects:

Adjusting the flow rate: The flow rate of the metering pump should be adjusted according to the process requirements to ensure that the speed and quantity of material transportation can meet the process requirements. By adjusting parameters such as the speed or displacement of the metering pump, accurate control of flow can be achieved.

Adjusting pressure: In some processes, it is necessary to adjust the working parameters of the metering pump according to pressure requirements. By adjusting the pressure sensor or control valve of the metering pump, accurate pressure adjustment can be achieved.

Adjusting accuracy: The accuracy of the metering pump plays a crucial role in controlling the process. By regularly calibrating the sensors or control system of the metering pump, the accuracy and stability of the material conveyed by the metering pump can be ensured.

Measurement pump manufacturers usually provide installation and debugging services for their products. They will dispatch professional technical personnel to assist customers in installation, ensuring that the installation process meets relevant standards and requirements. At the same time, they will also debug the metering pump to improve its accuracy and stability. In addition, metering pump manufacturers can also provide training and technical support to customers to ensure that they can operate and maintain the pump correctly. Therefore, when choosing a metering pump manufacturer, customers can consider whether the manufacturer provides comprehensive installation and debugging services to obtain a better product experience.

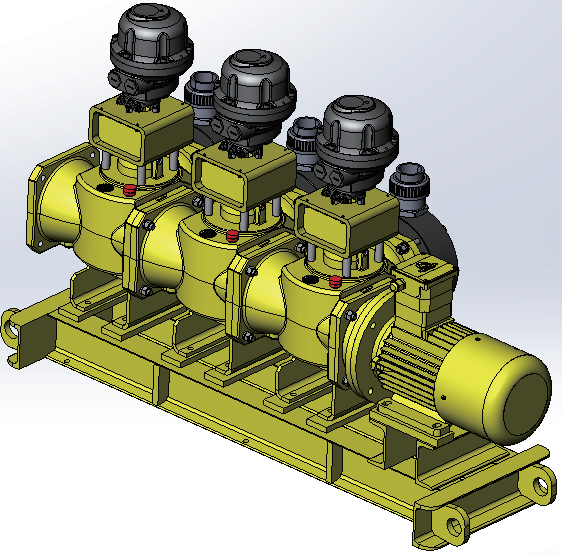

A metering pump is a device used for conveying liquids, whose main function is to transport liquids from one place to another and accurately control the flow rate of liquids. Measurement pumps are commonly used in industrial production to transport various liquids, such as chemical liquids, food liquids, pharmaceutical liquids, etc. The metering pump can adopt different principles and structures according to different conveying needs. Common metering pumps include diaphragm pumps, gear pumps, screw pumps, centrifugal pumps, etc. These metering pumps each have their own characteristics and are suitable for different occasions and industries.